In Jianming stone, quality is high on the agenda. It is quality instead of price that sells our products. It is the quality that makes JM Stone stand out, win the customers’ trust and loyalty and maintain the long-term relationship with them. Therefore, quality management is the top priority. With three parties involved, the sales who know the customers the best, the draftmen who understand the drawings the best and the QC who knows the production the best, JM strictly follows the Triple QC system in every project from beginning to end.

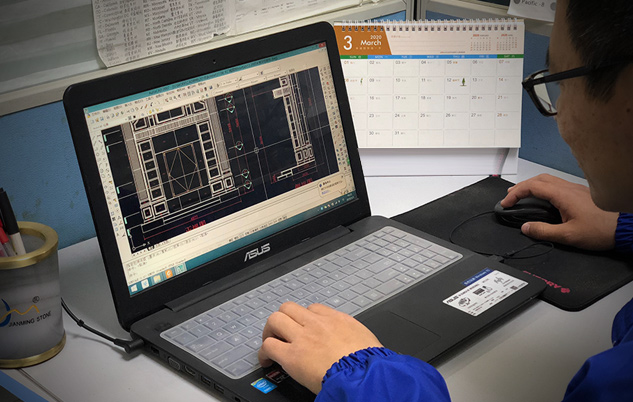

Shop Drawings

- With the ability to take apart the architect plan and create the fabrication tickets, JM is able to consider the assembling before the production and make sure there is no trouble in installing.

- JM strictly follows the Triple Drawings Reviewing System either the fabrication tickets are provided by the clients or created by JM drafting team to make sure no mistakes before fabricating.

- JM will provide the best suggestions and solutions to the parts which are not practical and operable in production or installation so that the architect could consider, change and choose the best design plan.

Stone Selection

- Knock down 2 pieces samples from different areas of the same block, get them polished and compared with the approved control samples to ensure the color matching and consistency.

- 3 people will be involved and review each block individually and make conclusion and decision together to make sure the right blocks without any defects like color deviation, cracking and flaws are secured.

- The blocks with same color ranges will be applied to the same rooms or areas to ensure color consistency even though that means we have to cut a block in different thickness like 3/4”, 1’’, 1 1/2‘’ and 2 1/2’’ etc., which is more cost-consuming and time-consuming.

Stone Fabrication

- Small details count in the quality control during production. 3 mock-up samples either for simple or complicated profiles will be made beforehand to learn the difficulties, the details to pay attention to and the best processing ways etc. before the mass production.

- Double QC system is widely applied to fabrication management. Besides the production managers and workers, the QC team will supervise and give instructions to workers in every processing procedure to make sure not pre-fabricated slabs with any crack lines and flaws are cut, the workers understand and follow the drawings exactly in profiling and keep the tolerance at +/-1mm, and the areas with small corners are well polished, etc. This enables us to have the quality control at the beginning instead of devoting to picking out the unqualified pieces from the finished products.

- Before getting the finished products packed, JM QC Team will inspect piece by piece again and make sure none of the unqualified pieces are packed and shipped out.

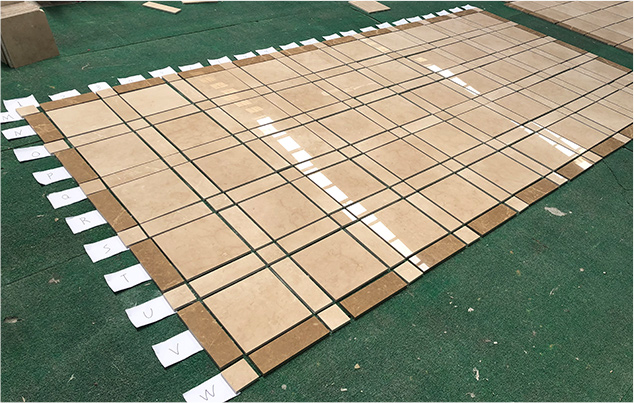

Dry-laid Out and Pre-assembly

- Do the layout and pre-assembly by area and make sure the pieces with profiles are exactly matched and the colors are transited naturally while within the control samples ranges and then labelled accordingly. The layout plan or labelling photos will be provided and ensure the clients follow exactly at installing.

- For the stone materials which require veins consistent matching or bookmatching such as white marble, good photos matters. In some cases, the UAV will be used to take photos or videos in order to present the best matching effect to the customers for approval.

Packing and Loading

- Before the packing and the loading, JM will take safety, convenience and easiness for installation into consideration and make the best packing schedule and loading plan which is making the most of the containers.

- JM inspectors will supervise the loading personally, clean the containers and make sure the crates are removed and put appropriately and safely. Small crates are put horizontally while long crates vertically and sliding pieces are added on the bottom for easier pushing and pulling. Besides, wooden and iron bars will be used to fasten the crates to ensure safety in transporting.

It’s one thing to have a team, while it’s a whole other thing to have teamwork. Great things in business are never done by one person, they are done by a team of people.